About High Temperature Heat Pumps

Heat pumps that can generate heat above 100°C are called high-temperature heat pumps. Aneo’s heat pumps can deliver energy in the form of process steam of up to 5 barA or 150°C. Steam-producing heat pumps can therefore not only replace traditional, fossil fuel-based boilers, but at the same time reduce the need for electricity.

Summary of technology

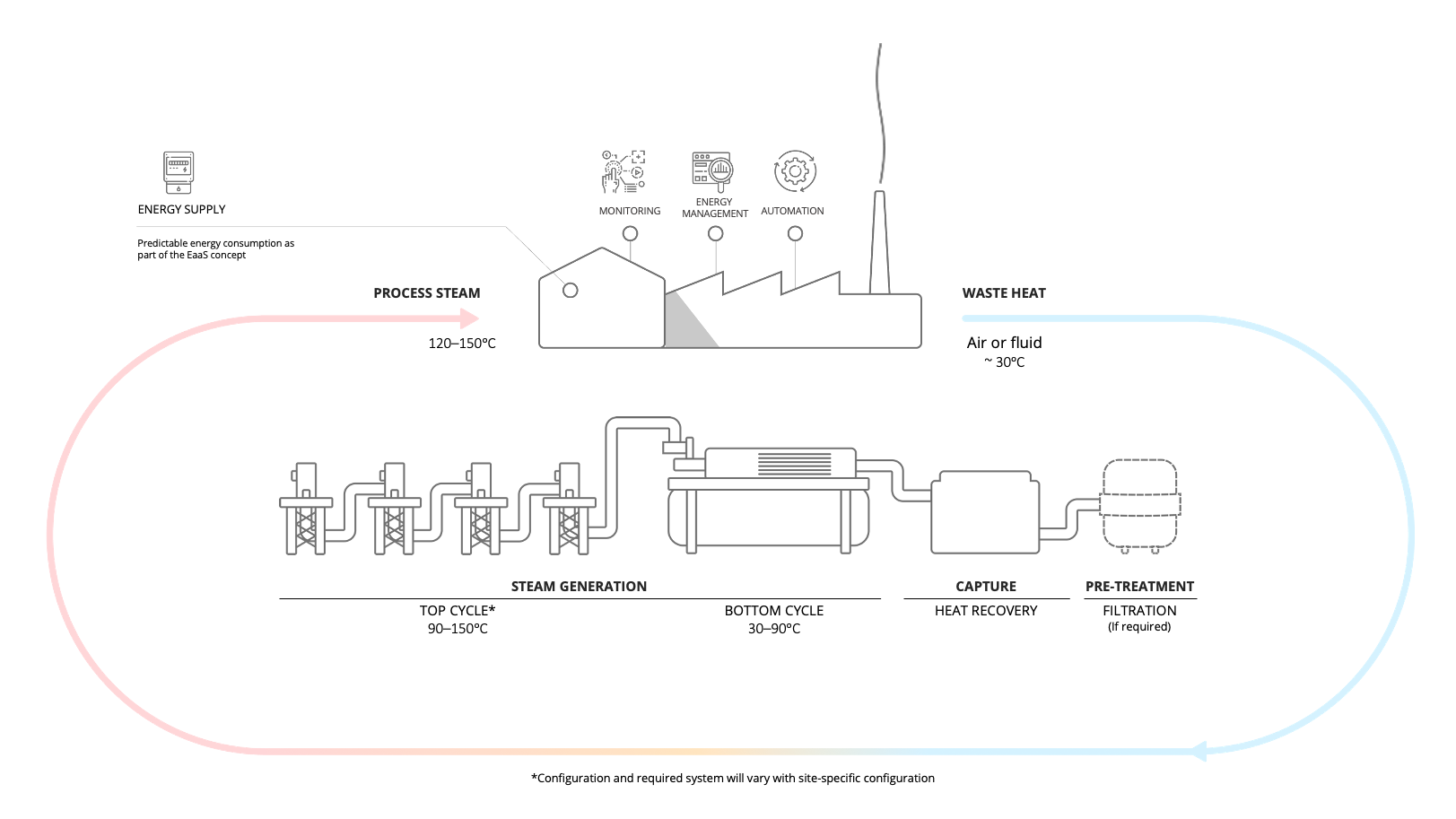

The core technology of Aneo is an integrated heat pump system which can supply process heat in the form of pressurized steam of up to 150°C or 5 bar(A).

The steam producing heat pump (SPHP) is standardized for excess heat temperatures between 20°C and 90°C. The SPHP integration includes an energy recovery unit for moist air, however also other excess heat sources can be integrated.

The recovered heat is transferred to a bottom cycle which upgrades the energy into low pressure steam. The bottom cycle uses Ammonia (R717) as working media. The low- pressure steam is further compressed by multistage steam compressors and can reach up to 5 barA/150°C. The multistage cascading also enables the usage of steam (or hot water) at lower temperatures or pressure levels which improves the COP of the system.

The principal layout of the SPHP is a combination of a closed loop bottom cycle and an open loop top cycle (typically known as Mechanical Vapor Recompression). The top cycle can also be integrated as closed loop according to process requirements.

The most relevant application areas are in the food, pulp and paper as well as chemical industry for processes like drying, evaporation, sterilization, thermal treatments or similar processes. However, also other application, process and plant integrations are possible.

The SPHP uses natural refrigerants such as Ammonia and Water as working media and heat carrier. Compressor types are centrifugal fans for the top-cycles and piston compressors for the bottom cycle. The pilot system is a 1.5 MW steam producing heat pump which is currently under installation and will start-up end of 2023.

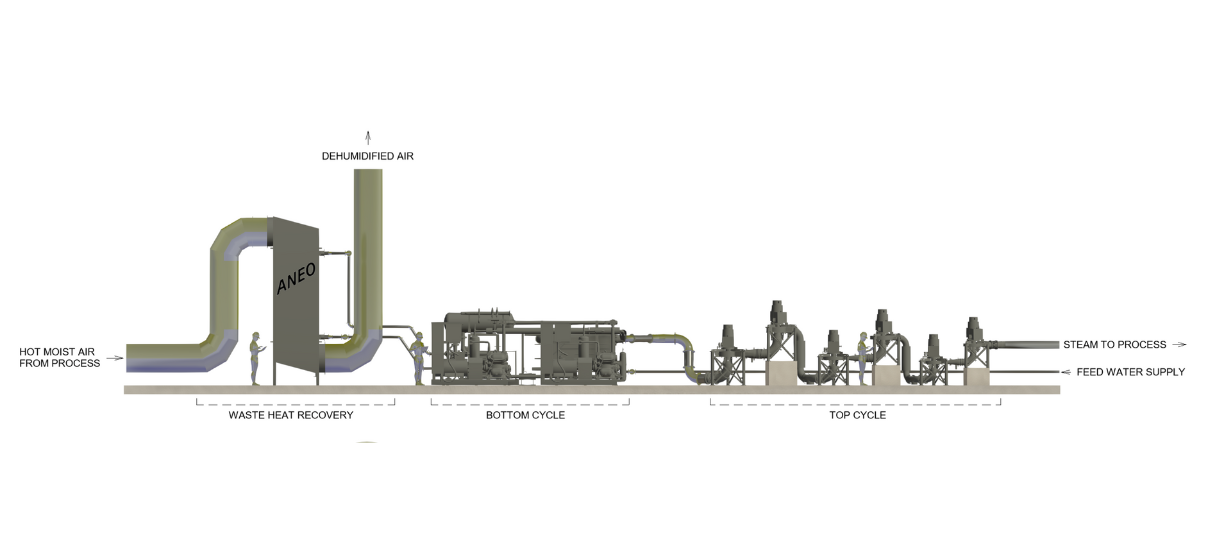

The sketch above shows how Aneo's complete heat pump system looks based on energy recovery from air and a steam supply of up to 7 ton/ h with a pressure of 4 bar.

Aneo is establishing and operating the SPHP systems onsite for customers through an “Energy as a Service” platform. The technology, integration, investment, reliability and technical risk as well as the service costs are part of the service platform. The customer pays for the energy supplied by the SPHP system.

The benefits of the technology

Every technology has advantages and disadvantages. HTHP will always reduce the energy demand and reduce the climate impact.

However, their integration is complex and requires in-depth process understanding. Compared to fossil boilers they have high investment costs and their operation requires a more detailed monitoring.

Aneo Industry will handle these downsides of HTHP for our customers through our Energy Platform so that the benefits of the technology are harvested today.

Facts about the technology

| Heat supply capacity: | 1.2, 2.5 and 5 MW (10 MW optional) |

| Temperature range: | Up to 150°C in the form of 5 barA steam.

Option for pressurized hot water with temperautre glides in the form of closed loop heat pump. |

| Working fluid: | Ammonia (R717) and Water (R718). |

| Compressor technology: |

Different compressor technologies for the bottom and top cycle. Centrifugal fan as well as piston compressors. |

|

Specific investment cost for installed system without integration: |

The system is available with "Energy as a Service" contracts. |

| TRL level: | TRL7-8 (Subsystem are on TRL8-9). |

| Expected lifetime: |

20-25 years (depending on operational hours). |

| Size: | Depending on integration and temperature lift. |

Project example

Aneo is currently establishing a showcase for the integrated SPHP system which is supplying 2 tons/h process steam. The heat is hereby extracted from a moist air exhaust, which is cooled down to 30°C while sensible as well as latent heat is recovered.

The heat pump is supplying hot water at 80°C and process steam with 2 bar(A) at 120°C. The total energy supply is 1.5 MW with a COP of 3. The energy contract includes a guaranteed annual operation for the customer.

Please reach out if you have any questions

Michael Bantle is an expert in high temperature and steam producing heat pumps. For 10 years he was developing this technology and their integration into thermal processes at SINTEF Energy Research before he joined Ohmia Industry. He holds a PhD in Energy and process technology from the Norwegian University of Science and Technology, and has a diploma in environmental and process technology from the University of Applied Science Konstanz, Germany.